There have been major changes at Strahman Valves, Inc., a world leader in wash down equipment and custom process valves, since Business in Focus profiled the Bethlehem, Pennsylvania based firm last September. There are new products, a new office in China, and the company, which was founded nearly a century ago, is growing at a rapid clip.

~

“I guess the biggest change we’ve had is the level of business we’re experiencing. The market is resurgent. I think a lot of it has to do with the strong economy in general. In the last two years, we’ve received some very significant orders,” says Augie Percoco, president and chief executive officer.

In 2017, Strahman Valves had 145 employees working out of the Bethlehem facility and at manufacturing branches in Mery, France and La Fox, Illinois.

“Currently we’re at 160, and we’re looking to add to that. With the workload we’ve got, we’re adding [employees] in Bethlehem and France. Right now, we have two shifts, and we’re gearing up for a third shift,” states Percoco. On top of that, the company opened a sales office in China a few months ago, “to serve our customers in the Asia Pacific Region, which is seeing a resurgence in growth.”

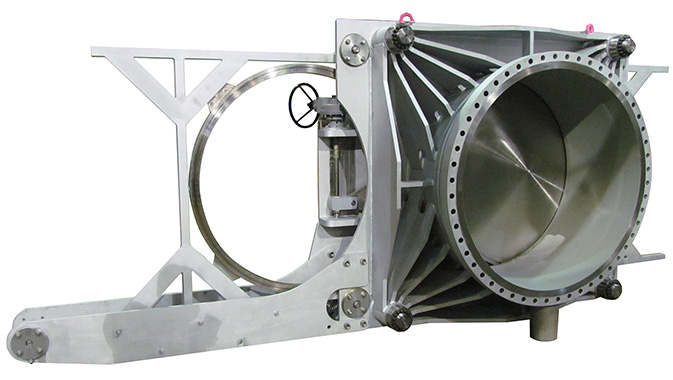

Strahman Valves offers a variety of products classed into four main categories: process valves, wash down equipment, pre-rinse equipment, and automated and safety valves.

Popular products include diverter valves, in the process valves category; mixing units, hoses, and nozzles, in the wash down category; spray valves and hoses for dishwashing, in the pre-rinse category; and thermal shut-off valves, in the automated and safety valve category.

“The section that generates the most revenue for the company changes from year to year. This year, the process valve business will probably be the largest revenue generator because it’s project-specific and [there’s many] projects going on throughout the world. The wash down business has been and continues to be very stable. It grows every year,” he says.

Strahman Valves has started getting more involved in sanitation products, including “ozone compatible hoses and nozzles,” he continues. A naturally occurring gas with powerful oxidizing qualities, ozone (O3), is “a tremendously effective disinfectant sanitizing product. The nice part of it is, ozone is environmentally friendly. It doesn’t impart any harsh chemicals in the process that you have to get rid of,” states Percoco. “We’ve seen some interesting projects in the wine and brewery industry where they’re using it for sanitizing vessels and products. It has a wide variety of applications that range from food processing to water treatment to commercial laundries and swimming pools.”

Strahman Valves now offers a portable ozone system as well as permanent CIP units to its customers. Both systems generate ozone for cleaning and sanitizing purposes.

The company is focused on designing and producing its own products. “Part of our strategic plan was to be a manufacturer, not a distributor. Just about everything is made here,” he says.

The main sectors served are food and beverage, oil and gas, petrochemicals, chemicals, and the polymer industries. So far this year, the biggest revenue-generating sector “would probably be oil and gas refining. Food and beverage is primarily the wash down products. The downstream oil and gas processes primarily involve our valves,” he says.

The company is currently making custom valves for use in a hydrocracking slurry process designed to enhance the refining of crude oil. Traditionally, crude oil refining results in “a residual waste. This waste can be up to eight to nine percent of a barrel of oil. With a hydrocracking slurry process, you can increase the yield on a barrel of oil from say ninety to ninety-two percent up to ninety-six to ninety-eight percent. We’ve been developing custom valves in conjunction with [Italian energy company] Eni,” says Percoco.

Custom work is one way Strahman Valves continues to stand out from the competition. The company specializes in designing and building specialty or one-of-a-kind products for clients.

“A few years ago, the French navy came to us looking for a specific valve to close off exhaust vents on their diesels when they surface. The valves had to open and close in under five seconds and had to operate at ambient temperatures and at temperatures over two hundred degrees. We developed the valve and an actuator that was able to fit in the space that they gave us. We exceeded their expectations [and developed a valve that closed] in three seconds. When a customer has something unique, they generally come to us. We sell solutions, not just products,” notes Percoco.

The company also embraces new technology to achieve greater efficiencies and capabilities. Strahman Valves uses three-dimensional (3D) printers, for example. Such printers turn digital designs on computer-aided design (CAD) files into three-dimensional objects through a lengthy layering process involving liquid plastic, metal powder, or other materials. The company uses its 3D printers to make samples of new parts or products before main production.

He says that customer service is one of the secrets of the longevity of this company, which was founded in 1921 in New York City.

“I think the biggest thing is our focus on customers. We’re also very careful in the processes we select. We make sure we have the resident expertise, so we can not only provide a product but provide solutions to our customers rather than just a valve or a nozzle,” states Percoco.

“For a small company, we believe very strongly in strategic planning. We have an annual planning process, and it helps us stay grounded. We know where we want to go, and we also determine what it’s going to take us to get there. We set short-term goals every six months and we track our progress to make sure we’re headed in the right course.”

Now that Strahman Valves is in expansion mode, the company follows certain criteria regarding new hires. “The big thing we look for is employees who are willing to learn. We try to find people that are inquisitive and willing to go the extra mile for customers,” he says.

New employees receive enticing benefits and opportunities. “We believe very strongly in promoting from within. If we hire somebody in assembly and they have a good aptitude and show interest in becoming a machinist, we will support them with on the job training and send them to technical training and pay their tuition. It gives them a career path and gives us a much stronger employee,” Percoco says.

The firm also wants workers who are safety-minded. The company holds regular safety meetings at which specific topics are addressed with employees “whether related to operating machinery or welding or air safety. On a weekly basis, our safety manager sends out bulletins which have safety tips: how to avoid accidents, stay safe. Because we’re an ISO facility, we have safety audits which are done quarterly to make sure we are following our own procedures and haven’t adopted any bad habits,” he adds.

Strahman Valves has obtained SIL-2 (Safety Integrity Level) certification from the International Electrotechnical Commission (IEC). On the quality front, it remains ISO 9001 certified and focused on maintaining quality.

“We have a policy of one hundred percent inspection. We check incoming material to make sure it’s consistent with what our specs are. Anything going out the door, we also inspect to make sure every product we’re putting out is operating the way it’s supposed to,” explains Percoco. “With our welders, we renew their welding certifications to make sure they’re up-to-date with the most current techniques and processes. So we try to make sure all of our staff is operating with the most up-to-date and effective processes.”

Strahman Valves attended the National Restaurant Association trade show in Chicago this May and is scheduled to attend the American Society of Plumbing Engineers (ASPE) conference in Atlanta in late September. The company has an online presence and does “email blasts on a monthly basis. We started doing postcards which give our customers ideas of new products that are coming out or anything new taking place within the company. We also have an outbound marketing program where we call our customers to make sure we understand what new projects they’re working on and let them know what services we can provide,” he states.

The CEO says the biggest challenge facing the company “is finding machinists and qualified personnel to work in our production facilities. In the United States, a lot of younger people have gone to more service-oriented careers. Not a lot have decided it would be good to know CNC (computer numerical control) machining or welding or assembling. That’s been a real challenge.”

The company has been working with a local school, Northampton Community College, to tackle this problem head-on. Strahman Valves has donated used equipment to the college, which runs technical and vocational classes, and has suggested setting up an apprenticeship program.

Percoco envisions a bright future as the company heads towards its centenary. “In five years, I think we’re going to continue to grow, continue to look for new acquisitions. My goal in five years is ambitious, but I’d like to see us reach $100 million [in annual sales] at one hundred years,” he says.