Toronto-based Nuspark designs, builds, assembles, installs and services automated and robotic packaging and manufacturing systems for a long list of clients, including some of the largest producers in the food, beverage, and automotive markets.

~

When Business in Focus called in late April, automation solutions firm Nuspark Inc. was preparing for a big move. “In two weeks, we are moving into a new facility – more than twice the size of our current location,” says Founder and President Michael Elent. The new site, located just down the street from the company’s existing head office, is around 30,000 square feet.

Nuspark will be moving its headquarters and two main divisions into this new space. “One division is primarily focused on packaging equipment. The second division does general automation and automotive automation,” explains Michael.

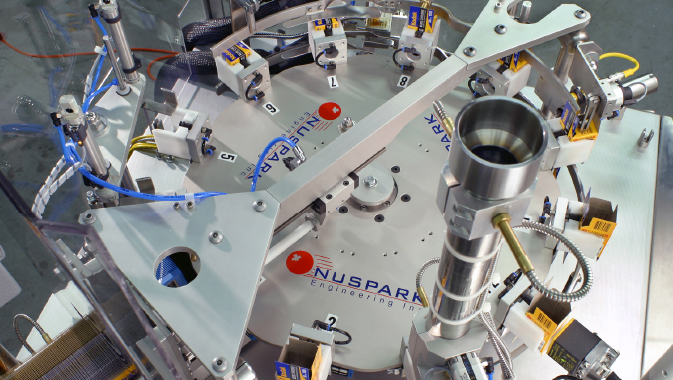

These two divisions are served by a single engineering department, and dedicated project managers handle assignments within each segment. The packaging equipment division specializes in cartoning, palletizing, case packing, top loading, coffee packaging, tray packing and forming solutions and custom applications. The general automation and automotive segment is focused on automotive fixtures as well as custom automated assembly projects.

While Nuspark serves a broad clientele, “our main customers are in the food, beverage and pharmaceutical industries,” Michael says. The firm has also devised manufacturing systems for customers in the personal care, consumer goods and, of course, automotive sectors. Major clients have included Nestlé, Maple Leaf Foods, Parmalat and Kraft.

In addition to designing and manufacturing automation and robotic solutions, Nuspark installs and services its equipment, North America-wide. The firm has a strong service department with over 50 years of combined experience who handle such work and has done over one thousand installations in total.

“Our equipment is in fifteen countries and in four continents. The majority of our equipment, however—eighty-five percent—is done for the North American market,” he says.

The engineering team consists of mechanical and electrical engineers from a number of different industry backgrounds. All told, these engineers boast over ten decades worth of combined engineering and robotics experience that have led to the company having more than thirty patents.

Among other capacities, Nuspark has an in-house machine shop and facilities for welding and electrical controls and panel design and assembly. The company uses Canadian-made parts when it can, outsourcing computer numerical control (CNC) machine tools, laser cutters and water jet equipment to local companies and utilizes Pro/ENGINEER and Autodesk 3D Inventor software for design purposes.

The automated solutions that Nuspark comes up with are made from “standard machinery, which we then customize to fit the needs of the customer,” says Dan Elent. “But it was not always this way; originally all our machines were custom, designed for a specific application. As our engineering database and industry knowledge grew, we began designing standard modules which could each be used for a number of applications. By combining the most commonly used and effective modules onto single frames, standard machines began to form, bringing us to our current line of machinery. This organic growth of our product line has resulted in incredibly efficient and cost effective machinery.”

Nuspark does outsource its robotic assemblies. It primarily uses robotics from FANUC and ABB, depending on customer preference, and the company is an authorized FANUC integrator. Nuspark’s industrial controls come from Bosch, Allen-Bradley, Omron, Schneider, and others.

Many of Nuspark’s solutions involve vision sensors, and the firm is looking to get into 3D vision. The next frontier in vision sensor technology, 3D vision enhances the ability of automated and robotic systems to differentiate parts in manufacturing environments and greatly increases the flexibility and effectiveness in performing other tasks.

After coming to an agreement with a customer about an automation or robotic system, the project moves into concept development which entails coming up with a ‘process flow’ and engineering requirements. After this step, the engineering phase begins. This involves 3D design software and input from the client. Manufacturing and assembly then follow.

An in-house factory acceptance test of the equipment takes place next. If everything passes muster, the system is shipped to the customer and is installed by Nuspark technicians at the client’s site. Nuspark can also take care of customs and insurance requirements.

Nuspark works with clients at varying stages of the automation spectrum. If a client does not have automated manufacturing equipment, Nuspark can make an assessment and develop a plan for moving to automated machinery. If a client is already automated, Nuspark can offer suggestions for enhancements and upgrades, with cost-savings and boosted production in mind.

Michael, who has a degree in mechanical engineering and a Ph.D. in robotics, founded the firm in Toronto in May 1999.

“We started from scratch. We started with design work. Then we hired a few additional engineers, and after we started to build machines, we hired assemblers,” he recalls.

Nuspark currently has over fifty employees, up from forty-five last year at this time, he states. As for new hires, Nuspark wants employees that are “loyal, first of all, professional and dedicated.”

Down the road, Nuspark might have enough employees and business to warrant opening new branches. For now, however, the company just wants to get settled into its new digs before contemplating any new expansion.

Quality and safety are two vital concerns with any automated solution the company devises. To make sure its solutions are safe, Nuspark builds systems according to CSA Group standards. CSA Group is a standards development organization for both Canada and the U.S. “We are doing everything according to the code of CSA,” says Michael.

Quality is likewise stressed. “We have a quality control [process]. We have a list of things we have to check mark before any machine goes out the door,” he adds. Nuspark is also ISO 9001 certified.

For the last five years, Nuspark has been “very heavily involved in the single serve coffee (KcupTM) business. We did at least seventeen to eighteen lines for big customers like Kraft and Barrie House coffee,” Michael says. “I think we are one of the biggest experts in North America in KcupTM packaging equipment.” KcupsTM are used on Keurig coffee makers, highly popular single-serve packages of coffee.

He anticipates the company will continue to innovate and add new products and services into the future. “We are always developing something new,” he says.

For all the company’s vaunted technical expertise, however, the human factor plays a huge role in its success. “We started off as a family business: myself as the CEO, my brother, Felix Elent, as VP of operations, and now my Son, Dan Elent, has joined us recently in the marketing department. Over the years we have grown and now have an extended family with all the fantastic people that have joined us, a lot of whom have been working with me for the last twelve to fifteen years. We are one large Nuspark family. We have people from China, from Romania, from all over the world. I don’t know how many languages we speak here in Nuspark, but we all feel like one family,” Michael says.

“It’s a family company,” adds Dan. “We have a strong desire to take care of our employees as much as our customers, not to compromise on one for the other. It is as important for us to have happy employees as it is for us to have happy customers.”

To ensure happy clients, “we are extremely willing to go above and beyond for our customers. What makes us different from other machinery suppliers is our dedication to our customer; the project manager will answer the phone in the early hours of the morning and do what he can to keep you running,” he adds.

As part of this dedication, Nuspark offers training programs for clients. Customers can take part in both classroom and plant floor training on how best to run Nuspark automated systems. Among other topics, training covers basic operation, electrical and mechanical troubleshooting, machine adjustments that might need to be made, machine changeovers and setups. Refresher courses are available, and training can be conducted at a client’s site if preferred.

The company is also committed to its industry and is a member of the Association for Packaging and Processing Technologies, a non-profit trade group.

Nuspark is registered on procurement database ThomasNet and Packaging World and regularly exhibits at the annual Pack Expo Tradeshow While these have traditionally been expositions with an emphasis on packaging, “we are working on focusing on industry specific trade shows, so coffee trade shows, brewing trade shows. That’s what we’re working towards. We are also present in online publications, machinery specific publications,” says Dan.

Nuspark doesn’t really bother with Facebook, Twitter or other forms of social media, however. “We are not really present on social media. Nobody’s looking around for half-a-million dollar machinery there,” states Dan. Indeed, the reality is Nuspark’s main form of promotion is its own reputation for solid design and excellent customer service.

“Money is very important in a business, but for us, our reputation is more important. We are loyal to our customers—that’s why we have repeatable business from many, many customers—because we’re showing our loyalty. We support them every single moment they need us. It doesn’t matter if it’s a Friday, Saturday or Sunday,” says Michael.