Cope Plastics is a fabricator and distributor of plastic sheet, rod and tube with locations across the Midwest and is doing business nationwide. The company provides complete custom fabrication solutions from engineering and design to assistance with material selection and the manufacturing of quality, cost-effective fabricated parts.

~

Business in Focus spoke with the company’s President and CEO, Jane Saale, Vice President of Finance, John Theen, Vice President of Sales, John Lee, and a host of other enthusiastic members of the board about this thriving entity.

Dwight and Mozelle Cope founded the business in 1946, initially supplying the hobby field and industrial arts departments of high schools and colleges. The use of plastics in industry gradually increased throughout the 1950s. Due to the demand for cut-to-size plastics, the company began the fabrication and distribution of finished components. A new plant was opened in Godfrey, Illinois in 1958. The following year, a sales force was started with a large number of sales branches to follow. In 1972, corporate headquarters moved to Alton and a legacy of success followed.

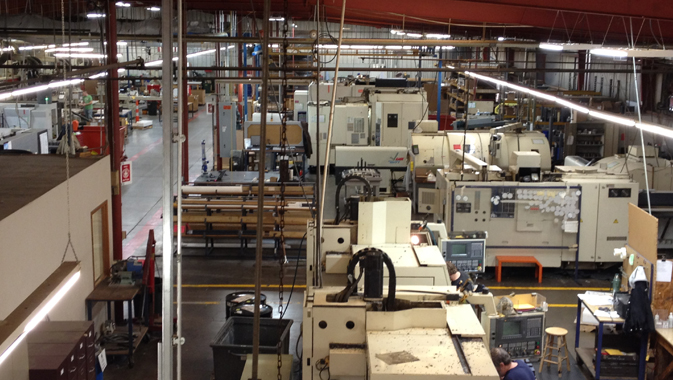

Cope Plastics continues to expand both the fabrication and distribution sides of the business. “One of our distinct competitive advantages is our manufacturing capabilities. We have a broad array of machining capabilities and a depth of knowledge that is unmatched in the marketplace.”

Not only has the company made significant capital investments in state of the art machinery, but the team has the technical expertise that can only come from decades of experience in machining plastics. Cope believes that there is no better source for machined plastic parts in the country.

Most of Cope’s senior leadership spent many years working for publicly traded companies before coming to Cope. “Family-run private companies allow us far more flexibility to change and react to market influences. There is a family culture in everything we do. Tenure is important to our company and to the family.”

This leads to the company’s biggest challenge and balancing act. While attracting and retaining the best people it can find, it also wants to ensure that the business grows as an internal provider of security for its company family and the tenured employees. Cope has a very low turnover for a $100 million company and that allows it to rely on plastics experts for making business decisions.

The fact that Cope is woman-owned is also very important to some of its larger customers and adds a definitive competitive edge. “We don’t overreach that women-owned business designation. We sell our capabilities, our service and our product. The National Women Business Owners Corporation (NWBOC) certification, which involves a rigorous certification process, will help strategically on certain accounts, but it is not what we rely on.”

Finding the right people for the plastics industry has been difficult given variables in unemployment and the market. At one point, Cope had major issues in trying to find experienced machinists. “I think the sales arena is easier to find qualified candidates. Machining and manufacturing gets a kind of black eye in the industry because of the perception that it’s a blue collar dirty job. It is quite the opposite here.” People that run the machines for Cope – in a clean atmosphere without the dirt and grime – must have expertise in programming, metrics and understanding of machines.

Cope has several internship programs in cooperation with colleges and high schools. The company also works with local colleges, in partnership with the Illinois Manufacturer’s Association, and is looking at STEM (science, technology, engineering and mathematics) programs in trying to come up with an accreditation or certificate program through several of these colleges.

“This will enhance and promote manufacturing and engineering. The end game would be our machinists. So we are helping with the curriculum, and the relationship with high schools is very strong. We have no objection to taking their qualified graduates and putting them through our own training programs.”

Cope works on multiple fronts to obtain the right people. It is building an extensive ‘fab lab’ (fabrication laboratory) centre in its local community college with the investments to run over the next five years. The donated money will give Cope an edge by being able to attract talented people to the college. “We believe that it is a good business plan.”

The company is a huge supporter of non profit organizations such as the United Way, Susan G. Komen, Friends of Kids with Cancer and its local beautification board. Its involvement also includes The St. Louis Blues 14 Fund, the St. Louis Blues hockey team’s charitable foundation (all members in the interview are big hockey and Blues fans).

“As for public versus privately held, we are all very encouraged to be involved in the community which ranges from serving the Illinois Chamber of Commerce board to the local church board along with the smallest community boards. We are also heavily involved in our trade association: IAPD (International Association of Plastics Distribution).”

Cope’s CEO and President Jane Saale is also the current IAPD president. The company’s Vice President of Administration, Jeff Maynard, sits on the education committee and helps to establish the education process throughout the industry. Cope’s Recycling Manager, Andy Fergurson, is on the environmental committee and Cope’s VP of Finance, John Theen, is Vice Chair of the Government Relations Committee.

The company has garnered many awards for its work and practices. The Riverbend Growth Association presented Cope an award for Community Involvement this year. Its trade association, International Association of Plastics Distribution, gave Cope an Education Circle of Champions award. Cope has also won the IAPD’s Environmental Excellence award for its heavy involvement in recycling programs and was awarded with Best Recycling Program for its recycling efforts at the IAPD Convention in Chicago. The company’s customer recycling program is another service that strives to keep plastics out of landfills. “The aim of this project is to be a mutually beneficial recycling program that will ultimately make a difference in the future of plastics.” Cope truly believes that this is something that sells the company and differentiates it.

As to its short term goals, Cope intends to maintain a stable company profile for its employees. Over the long term, Cope will continue to be a leader in both distribution and fabrication of plastics in the country. “Copeland” is the area of the Midwest where its branches are located, but the scope of the company’s business is on a national level.

“We are looking to expand and set our Cope footprint in acquisition or organic expansion in areas outside of Copeland. We started with distribution, but as time goes on you need to differentiate yourself.”

Cope has gone from eighty percent distribution and twenty percent fabrication to sixty percent fabrication and forty percent distribution. “It’s easier now to get parts across the country in a relatively short period of time.” The company used to be limited to the Midwest but has expanded and can land big fabrication parts business without having a physical location in that particular city.

Another long term goal has to do with finding the employee and business balance. Cope thinks of its employees first when it comes to making business decisions which is one of the reasons that people want to work there. Profitability is the lifeblood of any organization, but the company wants to also look at how the entire Cope family is affected, which will filter into business decisions.

Cope wants to develop and form partnerships with its vendors and customers. “We want a long term partnership for the mutual benefit of our vendors, customers, Cope, employees – the whole bit. It really is a philosophy of how we do business; our quality statement is: Your Vision, Our Quality, One Partnership. Aside from being transaction based, we want to form strategic partnerships, so that everyone benefits.”

Cope’s partnerships with its vendors are crucial to its business and it is particularly appreciative of its top five vendors: Quadrant Engineering Plastic Products, Cast Nylons Limited, Bayer Material Science, Plaskolite Inc. and Röchling Engineering Plastics.

“When you add it all together you get this real feeling about what Cope is. We try to be all-encompassing, and that is the philosophy of the ownership and management group here as we want everyone to be involved. On our website is our owner’s philosophy and core values, which we live by every day.”