In just seven years, Urtech Manufacturing Inc. has grown from a modest, two-person business working from a 2,500-square-foot building to a well-respected and successful electronics manufacturing company with almost two hundred full-time staff and a facility of over 70,000 square feet.

~

Urtech Manufacturing is based in Burlington, Ontario, Canada and has expanded to include offices in strategic locations known for technological innovation including Toronto, Kitchener and the city of Bristol in the United Kingdom.

Urtech has grown naturally for most of its history but recently expanded through the acquisition of Jolt Technology, an electrical and electronic contract manufacturing business established in Florida’s Ft. Lauderdale over 25 years ago.

“I am working on growing Urtech Manufacturing—taking it to the next level—and hope to see it double this year,” says company President Greg Gehl. Jolt is his first acquisition, which he hopes to follow with another later this year and possibly more in 2018.

By acquiring Jolt Technology and its 20,000 square-foot manufacturing space last October, Urtech took a bold step forward in the arena of customized electronics manufacturing and speedy prototyping services for its customers across North America.

The acquisition saw Jolt commence operations as Urtech Florida LLC. “We look forward to working with customers and demonstrating our commitment to delivering exceptional manufacturing services.”

Gehl has held a senior management role at Tier 1 global electronics manufacturing services provider Celestica Inc. and served as director of manufacturing at Evertz Microsystems. While working for a local original equipment manufacturer that developed broadcasting equipment, he realized that much of the business was being outsourced abroad. “That’s when I started looking at the pricing models they were using overseas, and I realized we could do the same here with the same pricing, but better quality, better turnaround and better communication.”

The company adopts a hands-on role with clients in providing design for manufacturing and provides feedback, tests, improvements to manufacturing and a host of other processes. The company was recently ISO 13485 recertified for medical products such as diagnostic devices.

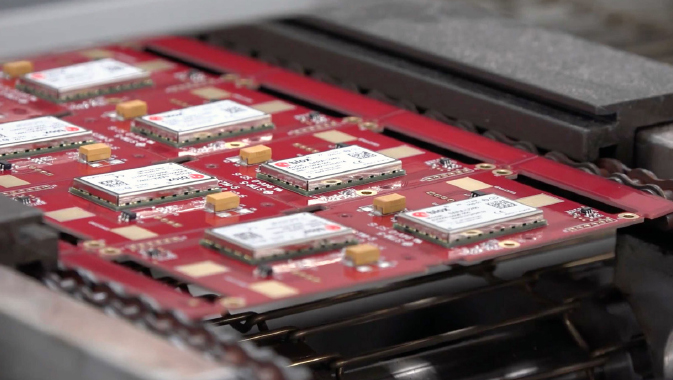

Urtech Manufacturing has the skills, technology and engineering expertise needed to offer precisely planned and implemented prototype, production and end-of-life capabilities to its clients. Urtech’s capabilities range from advanced surface mount technology placement equipment to selective solder, box build, direct order fulfillment and more.

The company unveiled hardware accelerator space UrStart this past April, and this will primarily benefit companies that are ready to build prototypes and launch volume products. Gehl says it was started because there remains a significant lack of assistance for companies developing hardware.

“The hardware folks tend to have a harder time finding a place that will cater more to what they need,” he states. “Software people need a computer and a desk, and that’s all. For hardware people, they need what I have: the equipment set, the skill set to be able to manufacture these products.”

UrStart can meet hardware development requirements such as services, network and mentorship and provides companies with the opportunity to connect with other start-ups at different points in launching a product. “So by putting the accelerator right with the manufacturing partner, it eliminates a lot of hassles where they have to actually go and try to find somebody to build their product. I’m right there.”

Timing is critical to beating the competition when bringing new products to market, and, realizing this, Urtech provides fast turnaround times for prototypes.

A LEAN manufacturing model at the production stage of a product’s lifecycle, combined with careful material and component sourcing are important methods of lowering costs. It also works with customers to refine their supply chain and reduce logistics costs.

“We are always working on our processes and how to make them better and more LEAN. I’ve got about five black belts on my team right now, so they are continually working on processes and trying to get them better. And that’s where we work very closely with our customers, and we have a great relationship with them. We have them come to our plant, and we work directly with them on their product launch using our Lean manufacturing processes.”

Because the company has headquarters in Canada, operations in Florida and multiple offices, customers receive the best possible customer service, close to home. “We have a lot of local customers to come to our factory and sit there and watch their product being built, then go home to have dinner with their families, instead of having to fly to Asia,” says Gehl. “It’s a good thing for our engineers to experience, and customers can see if there is anything that needs to improve to make the manufacturing process better as well.”

Due to client need, Urtech increased the number of shifts it runs from two to three every day. It continues to grow at an impressive rate. In just the past five years, the company has seen 1,300% growth. The company is on target to double again this year and is eyeing further acquisitions and growth.

“We are definitely competitive with the overseas market. We are known for our quality and our capability to be able to handle the toughest component out there,” comments Gehl. “So in our industry, doing a .2 mm pitch components—that’s tough. We do that kind of stuff.”

Urtech is able to take on virtually any project and regularly works with some chips costing $20,000 each. It is not unusual for the company to create single prototypes. It can also make small runs of ten pieces or a million units a year.

“We can pretty much handle anything, and we do volume products as well. Some people think, ‘If I do a million units a year, I’ve got to be in China.’ No, you don’t. Anybody who has dealt with overseas knows that if you are building products, especially in volume, you have to have people over there watching to make sure it gets done. By working with Urtech in North America, clients also save on importing costs, instead of having their products sitting on a boat or a plane.”

Since forming in 2010, Urtech has worked with clients on all their electronics manufacturing needs from prototyping to production and end-of-life with the utmost respect for quality, professionalism and North American-based accountability at every stage.

“We take our customers’ technology and help transform it into their end product and deliver it to their customers. So we do the whole gambit—everything from the beginning manufacturing to shipping the product,” says Gehl. “So we take care of everything for them.”