Headquartered in Burlington, Ontario, Cogent Power Inc. is the largest manufacturer of electro-transformer components in Canada. The firm has operated in Canada for over four decades and has sister companies in Sweden and the United Kingdom. Cogent is run as part of a European group of companies owned by Indian conglomerate, Tata Steel.

~

Cogent Power Inc., which supplies components and materials for motors, transformers and generators, is having a growth spurt. The firm is rapidly expanding, in terms of both revenue and personnel. According to President Ron Harper, Cogent’s success can be partly attributed to the company’s embrace of lean manufacturing and continuous improvement principles.

“If you look at our growth in the last few years, we have applied principles and thinking with lean, created capacity that’s allowed us to grow without adding a lot of significant resources in terms of equipment, raw materials and, to some degree, people. Those efficiencies gained through the lean process have been redeployed, enabling our business to grow,” says Harper.

Projected revenues for 2016 are $150 million to $180 million, up from $150 million last year. “We’re looking at something in the neighbourhood of ten to twenty percent revenue growth. If you take the last five years, our overall growth is probably in the neighbourhood of fifty to sixty percent,” says Harper.

Many of Cogent’s 330 employees are recent additions. “We probably added 120 people in the last twenty-four to thirty-six months.”

Cogent first started getting into lean and continuous improvement principles in late 2003 for several reasons. “Part of it was a corporate initiative from some of our other groups and businesses, but, at the same time, we were starting to get actively involved in a couple manufacturing organizations that were practicing lean. It started more out as a corporate initiative, but within a couple years of that, we started doing it more for ourselves than as a corporate initiative. It kind of built from there.”

The decision to embrace these principles was not just about boosting the bottom line either.

“Most people look at continuous improvement as a cost reduction [strategy]. We take a very different approach. We look at continuous improvement with two different objectives. One is continuous improvement to create more value for our clients. Number two, we try to use lean to create additional capacity for the resources we’ve got. You might create more costs, but we look at expanding capacity as opposed to reducing costs alone,” says Harper.

The Cogent boss isn’t throwing around buzz-words; the company runs a vigorous training program to get staff up to speed on lean and continuous improvement concepts.

“We have, at any given time, three or four different people from our operating team go through a three to six months training assignment: on-the-job training, classroom training, application and experiential training, with respect to implementing continuous improvement and lean work projects. In total now, somewhere between thirty to thirty-five people have been through the program in the last five-six years. It’s been a really good enabler of deepening the understanding of continuous improvement and lean at our operating team level.”

Other continuous improvement tenets that Cogent follows include eliminating waste, improving processes, generating more value for clients and adapting a flexible, agile employee mindset. The ultimate aim is to establish a people-centric culture, in which employees are valued and empowered, says Harper.

The Cogent website puts it this way: “A collaborative spirit and approach requires trust – both in yourself and the other members of your team. To create an environment of trust requires openness and vulnerability; personal responsibility and credibility.”

This spirit of collaboration is reflected in the company’s propensity for establishing “long-term connections with all the businesses and people we deal with – inside and outside the organization. That’s an important part of our ability to create sustainability and success in the future – a platform with which we can make things like continuous improvement and lean work by creating challenging and fulfilling work for all of our team,” says Harper.

A spirit of efficiency, meanwhile, pervades the technical side of the business. The company’s mandate “is to deliver on time and in full – every time!”

To this end, Cogent promises a secure, well-run supply system. Orders can be placed directly with the company through a material requirements planning (MRP) link – a computer-based production and inventory management system. The company uses wireless barcode scanners to record master coil inventory origin, monitor production, ensure delivery dates and track product throughout the company’s entire manufacturing process.

Cogent is being recognized for its abilities and unique qualities. It won a 2015 Ontario Export Award for Leadership in a ceremony held last November by Glacier Media in partnership with Canadian Manufacturers & Exporters. Cogent was a finalist in the same show, which was held in Mississauga, Ontario, for the category of Manufacturing & Resources (large manufacturers division).

In April 2015, Cogent won the Burlington Economic Development Corporation (BEDC) Business Export Award. This, according to Cogent, “recognizes the local company that has demonstrated strong growth in exports and significant contributions to the local community through employment, community contributions and economic development.”

While Harper is pleased by such industry honours, these awards have not gone to his head. “The recognition is nice and good for our teams to get that validation and recognition, but I don’t think we were specifically looking for that kind of recognition,” he says.

Of course, it is not all smooth sailing at Cogent.

“I think one of the challenges we have is that all of the biggest developments in engineering, technology, raw materials, et cetera, are being done in Asia. So, I think there’s a large opportunity for us to advance our capabilities in terms of electrical engineering capacity,” states Harper.

As for raw materials, “we get probably right now twenty-five percent of what we purchase from the U.S., and twenty-five to thirty percent is from sister companies within our group. The balance of the material generally comes from one of a few different Asian sources – Japanese, Chinese predominantly.”

When Cogent does business with American companies, it buys and sells in U.S. dollars. That way, the firm avoids being gouged by the lopsided U.S./Canadian dollar exchange rate.

A decade ago, Cogent had operations in Monterrey, Mexico and Bridgeport, Connecticut. “We ultimately closed the U.S. and Mexican operations and consolidated here [in Burlington],” explains Harper.

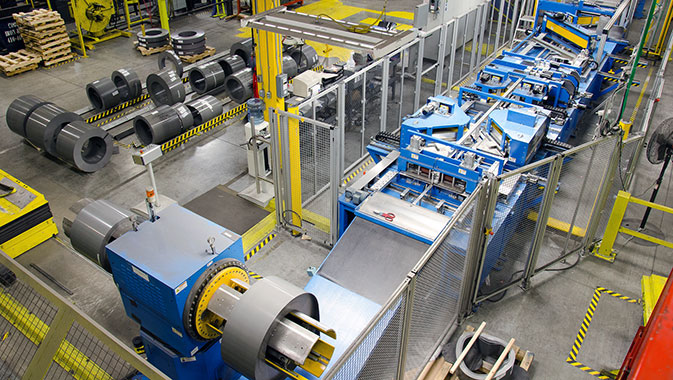

Further changes followed. In October 2015, for example, Cogent expanded its Burlington operations.

“What happened last year, we kind of overflowed our existing facility. There are a number of production and warehousing spaces in and around Burlington and Hamilton [Ontario] over the last couple years that we’ve added on to as we’ve grown. What we did in 2015, we just worked with a local developer and constructed a new facility adjacent to our existing one and just consolidated all of those operations,” says Harper. This new facility takes up 125,000 square feet.

Despite the construction of the Burlington building, there are no immediate plans to reopen the U.S. and Mexican facilities. Reopening “is unlikely in the U.S., but I can’t rule anything out. It depends on client needs. I could see the potential at some point in time, expanding into the U.S. more [and having] more operations in Mexico, but nothing’s imminently planned at this point,” says Harper.

Which is not to say that the company does not have big plans for the future. “We’re looking at some options. Our market position has traditionally been specifically North America, but we are looking at the possibility of expanding that with some of our affiliations,” says Harper.

“Our goal is to grow and strengthen the business and build on the strength we’ve got, whether that’s through organic growth – and most of our growth at this point has been organic – or through acquisition, has yet to be determined. So, our goal is to grow, but to be too specific about that growth, given the general volatility of the steel industry right now would be [kind of like looking into a] crystal ball.”

Harper has a clear vision of what he wants Cogent to become. “Our business needs to have a bigger international footprint. It needs to be more advanced in terms of automation. It needs to be more progressive in terms of the application of engineering. I think there’s a large role or available space to help the entire transformer industry be more effective, healthy and forward thinking.”