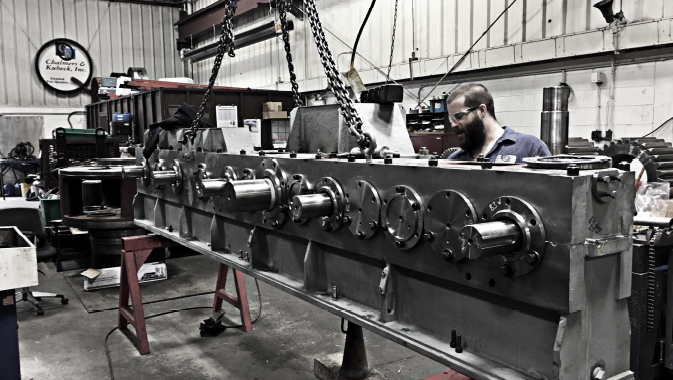

Chalmers & Kubeck, Inc. is one of the largest independently owned and operated industrial service providers in the eastern United States, with its headquarters, main machine shop and main valve shop all located in Pennsylvania. It is a third-generation family-owned business with offices spread across the eastern seaboard, from Massachusetts to Georgia. From its humble beginnings to today, Chalmers & Kubeck has taken great pride in making sure its customers are successful.

~

Chalmers & Kubeck got its start in 1950 when John Kubeck and Doug Chalmers, two machinists working at Atlantic Refining Company, decided to go into business together and started rebuilding machines after work, in their garages. After two years of hard work, they were able to support their families with just their work at Chalmers & Kubeck. Eventually, they rented space at Aircraft Welding in Brookhaven to refurbish steel mill rolls. “Business grew and soon they were doing work for General Electric,” says Chalmers & Kubeck Business Development Director Chadd Criddle.

Their company made the news when it fabricated the monkey life module for G.E. in support of the U.S. space program. It eventually purchased the Aircraft Welding facility in Brookhaven and expanded, opening a valve division to provide service to the local oil refineries. As machine shops across the Delaware Valley closed, Chalmers & Kubeck acquired massive machine tools from Baldwin Locomotives and, later, Westinghouse Electric. “We have a very good history with Westinghouse Electric,” adds Criddle. “They used to be located in Lester, Pennsylvania and were later acquired by Siemens. So, we now do a lot of [original equipment manufacturing] for Siemens as well.”

The company eventually outgrew the Brookhaven facility and relocated to the I-95 Industrial Park in Aston, maintaining the facility in Brookhaven as a warehouse. At the Aston facility, John Kubeck’s sons Jack and Dennis took over the day-to-day operations of the company and continued its incremental growth by adding a gearing department and a computer numerical control (CNC) manufacturing department. Dennis saw another opportunity as a local Flowserve Engineered Pump shop was closing and brought their management team on board at Chalmers & Kubeck. He successfully combined their technical knowledge with C&K’s machining expertise to overhaul and upgrade pumps with a unique level of responsiveness. To make space for this new department, the valve shop was relocated to a new 27,000 square foot facility around the corner. Just like the main shops, the valve shop had a business model built around multiple shifts and high capacity throughput for industrial outage turnarounds. The most recent expansion of capabilities is a thermal spray department to expedite shaft repair, restore critical dimensions, and upgrade material surface properties.

“The history of Chalmers & Kubeck is a testament to the American Dream,” says Criddle. “For John Kubeck – my grandfather – who was the son of a poor first generation immigrant from Europe, it’s a tremendous success story built on hard work and dedication.”

Today, the company is dedicated to keeping industry in North America running efficiently. “New valve sales and service (relief valves, line valves, and actuators) represent approximately half of our business while the other half is industrial manufacturing and maintenance,” he explains. “It’s sort of a complex business. Our main machine shop in Aston, Pennsylvania is organized into centers of excellence for CNC machining, engineered pumps, gear services, rotating equipment repair, field machining, surfacing technologies (thermal spray and grinding), and last but not least, welding and fabrication.”

“The calling card at Chalmers & Kubeck is emergency maintenance,” says Criddle. With its comprehensive set of in-house capabilities and dedication, Chalmers & Kubeck gets its customers back online as soon as possible, minimizing any financial losses they might have. “It speaks volumes when the semi-truck shipping your re-built part is loaded onto a chartered C-130 cargo plane and is then flown to the international airport closest to the customer’s site,” he adds. “It’s pretty remarkable when you see something like that. When people are in these situations – losing a million dollars a day – they give us a call.”

“It also speaks volumes when major industrial OEMs, faced with an emergency repair, knock on your door because they know Chalmers & Kubeck can repair one of their products quicker than their own manufacturing group, in-house. Even if they have the same capabilities, they’re just not set up to be service shops, at least, not emergency service shops” he says.

What sets the company apart is a combination of skilled and talented employees coupled with an amazing facility that has overhead cranes capable of lifting more than fifty tons and machine tools with huge working envelopes. For example, one of its vertical CNC turning centers can handle parts thirty-two feet in diameter and one of its horizontal CNC milling centers can handle parts thirty feet long on its bed. And several years ago, the company upgraded its form grinder to a state-of-the-art HÖFLER 2000, which is complete with on board checking and diagnostics for manufacturing precision ground gearing up to 2M in diameter.

The company’s Gear Department Manager was even elected to the American Gear Manufacturer’s Association board of directors. “This doesn’t usually happen unless you’re an OEM. We might actually be the first. So, it speaks volumes to who we are as a company and the respect that we get out there,” says Criddle.

Chalmers & Kubeck prides itself in having helped local nuclear energy utilities save millions of dollars. “We would work with them by utilizing state-of-the-art materials and maintenance techniques to improve the reliability and long-term performance of their engineered pumps,” he explains. Some of the advanced materials include carbon composite bearings and wear rings along with incredibly hard ceramic thermal spray coatings. Utilizing these materials, bearing clearances were reduced resulting in decreased pump vibration and significantly extending the intervals between overhauls.

“Another major accomplishment testament to the success of our 10CFR50 Appendix B nuclear quality program is our place on the approved suppliers list to perform safety related repairs for four different nuclear utilities,” adds Criddle.

It also takes great pride in its unique approach to marketing. “Our web presence is minimal,” Criddle explains. “The vast majority of our marketing is face-to-face and word of mouth. Most of our marketing is called ‘high-touch,’ where we’re in front of our customers talking about what we can do. But more importantly, it’s us trying to understand our customers’ needs and their recurring problems.” It goes out of its way to help customers find solutions.

In the valve, actuation and instrumentation world, Chalmers & Kubeck comprises the largest network of General Electric authorized Green Tag centers on the East Coast. “We’re a commercial stocking distributor for the G.E. Consolidated relief valves, and our eight million in new valve parts inventory is tailored so we can respond quickly to the needs of our customers,” says Criddle. “Chalmers & Kubeck is also a master distributor for Limitorque Actuators, offering expert service and field support for balance of plant operations, as well as a distributor for Clark Reliance level indication and control instrumentation.”

In the machining world, it manufactures an incredible variety of small batches of parts for major industrial OEMs. These involve complex fabrication, machine work, and exotic materials. “Much of it is power and heavy industry related,” he says. “With respect to affiliations, the most prominent is our status as an authorized repair center for Siemens Flender gear drives.”

Chalmers & Kubeck is a leader in efficiency through the flexibility of its products. “We also aim to make our shops more efficient, whether it’s vending machines for shop safety supplies and tooling or laser trackers to help with layouts, complex set-ups, and dimensional verification, we’re always looking for new technologies to help increase our productivity,” explains Criddle.

Presently, it is planning and scheduling software. Due to having so many different departments and service locations, it wants to make sure that its assets – from machine tools to employee skill sets – are utilized efficiently.

“This approach has been really great for us in these challenging economic times,” he says. “With the diversity of our business itself, if one area is not performing as well due to economic conditions, we can flex employees to different areas. In most situations, that has helped us avoid layoffs, and I think that’s a great thing.”

The company wants to make sure its customers are successful. “That means different things to different customers and can change depending on the situation,” explains Criddle. “But, at the end of the day, it’s about providing value. We’re there for our customers – to support them. That’s very important to us because we’re in this for the long haul, and we want to make sure our customers are there with us.”

In the upcoming years, Chalmers & Kubeck will mark a transition as it moves its leadership team to the third generation. “In addition to our tried and true ‘high touch’ marketing, there will be increased focus on technology as we strive to gain efficiency throughout our organization,” says Criddle. “It’s an exciting time, and we’re all looking forward to making Chalmers & Kubeck better for our customers, as well as for our employees.”