dlhBOWLES is a newly merged company, formed when Bowles Fluidics Corporation and DLH Industries Inc. joined forces on June 30th, 2015. Both businesses provided market leading engineered plastics and fluid flow solutions for the automotive industry and for consumer products, making the new partnership an ideal fit.

~

“There are a lot of companies that can come together and they just become bigger,” says CEO John Saxon. “We are becoming better. [The merger] is providing us with tremendous opportunities.”

The merger

Bowles Fluidics Corporation had been a world-class developer and manufacturer of fluid distribution products for the last 50 years. Known for its employees’ keen minds and problem solving skills, the company provided innovative products at component, sub-system and system levels in the automotive and non-automotive markets. Product offerings ranged from automotive hose assemblies, windshield washer nozzles, headlamp washer nozzles, and washer pumps to consumer products such as showerheads, spa nozzles and irrigation nozzles. “Bowles Fluidics Corporation was the world’s first and best supplier of fluidic solutions for washer nozzles and for consumer sprays,” Mr. Saxon details.

DLH Industries Inc. manufactured plastic air and fluid handling assemblies, tubing, hoses, and profile extrusions. “Our niche on the DLH side had really become providing engineered plastic solutions for [reducing weight in] things like turbo control systems, variable engine mount systems – things that otherwise might have been rubber or metals, but could be converted to plastic for weight savings in automotive,” Mr. Saxon explains. The company’s engineered solutions were produced through advanced manufacturing techniques including assembly, plastic thermoforming, tube and profile extrusion, and injection molding.

The merger of Bowles Fluidics Corporation and DLH Industries Inc. creates “synergy that comes from putting together what was predominately an engineering culture with what was predominately a manufacturing culture,” Mr. Saxon points out. “Together we offer unparalleled engineered fluid management solutions to the automotive industry predominately, but also to consumer products.”

dlhBOWLES is able to deliver a more complete solution than Bowles Fluidics Corporation or DLH Industries Inc. could on their own. “We support our customers through every phase of the engineering and development cycle.” A dedicated R&D team filled with industry experts drives innovation and customer-centric solutions, while the company’s leading edge equipment allows rapid prototyping using 3D printers. “If you are offering engineered solutions to your customer, many times they want to see a product in three dimensional form as opposed to just in drawing and in concept,” Mr. Saxon explains. “The 3D printing capabilities that we have are second to none in the industry. [We] respond very quickly to all of our customers’ needs.”

Automotive products

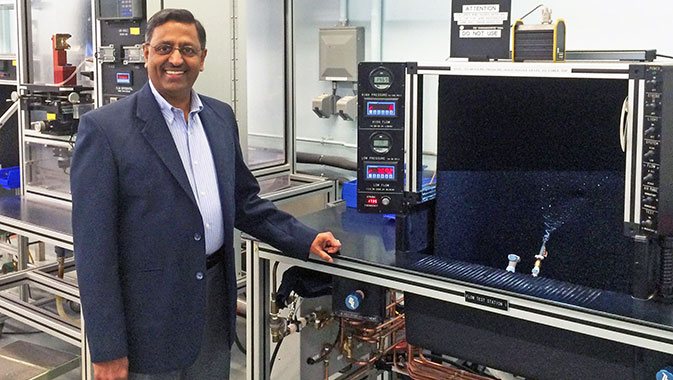

dlhBOWLES supplies a long list of products to the automotive industry, from windshield wiper systems, headlamp washer systems, and powertrain hose assemblies to vacuum brake systems and vacuum engine mount systems. “There is a whole range of products in automotive that we provide,” says President Sri Sridhara. Automotive customers include the Big Three (General Motors, Ford, and Chrysler) as well as the “new domestics” such as Toyota, Honda, and Nissan. “We touch most of the automotive OEMs.”

Bowles Fluidics Corporation and DLH Industries Inc. were both known for delivering customer satisfaction to these big name customers. “Our customers have recognized us,” Mr. Sridhara points out. “We won the General Motors Supplier of the Year award for six consecutive years. We have established extremely high quality ratings with all of our customers.”

Camera wash systems are one of dlhBOWLES’ most exciting new product categories. “The camera wash systems that we have developed in the last two to three years are new, innovative, ahead of the game and game changing,” Mr. Sridhara remarks. These systems were developed to meet an emerging market need. “[There is] a 2018 mandate from the Federal government that every vehicle must be equipped with a rear view camera,” Mr. Sridhara explains. The industry is still working out the best way to meet this mandate – and dlhBOWLES is leading the way. “The genesis of this began just a couple of years ago,” Mr. Saxon remembers. “The ramp up of the product is very exciting for us.”

As the industry worked through the details of incorporating video cameras into every vehicle, OEMs have quickly realized that automotive cameras needed to be cleaned regularly. “Customers like Ford have anticipated what the real need for consumers is, and have instituted an engineering policy of having wash capability wherever there is a camera,” Mr. Sridhara explains. The concept is quite straightforward – as is the fact that dlhBOWLES is a perfect fit for this technology. “If you have a safety product such as a camera, and it is exposed to the elements, it gets dirty,” Mr. Saxon points out. “The field of vision will become impaired and you need something to clean it. That segues nicely into our technology of fluidics because the fluidic spray actually provides an oscillating action that sweeps the lens clean. That sweeping clean with minimal fluid requirement from the rest of the washer system is really the secret. So it is extremely efficient and extremely effective at performing its duty.”

Mr. Sridhara adds, “Our company has taken the lead in proactively [creating] solutions for different contexts – the rear view camera wash, the front camera wash, the night vision camera wash – and packaging it within the vehicle space that is available, which is often limited.” The newly developed solution has been a huge success and is already commonplace or in development on several vehicles. “Of Ford vehicles that are already on the market, our camera wash is featured in Ford F-150 – the best selling pickup truck – the Explorer, and the Edge.” And that’s only the beginning, although mum’s the word on the details. “We cannot mention the names of ten other programs because they are not in the market yet, so it is confidential,” says Mr. Sridhara. In fact, dlhBOWLES’ innovative camera washing systems are beginning to catch on industry-wide with most automakers in the process of adopting solutions.

The next step

What keeps driving the company forward? “It is the attention to excellence, the passion to service our customers beyond a level that I think is common in business today,” Mr. Saxon states. “There is a pride in workmanship that is basically unmatched. We strive to be, and take pride in being, excellent at injection molding. We take pride in being excellent in extrusion and in assembly and in all facets of what we do.”

It takes a dedicated team to deliver that level of excellence. “We have a team that goes to work every day to please our customers,” Mr. Saxon says. “We come to work every day looking to solve the problem. There is a level of excitement and enthusiasm about the ever-changing automotive world.” The team’s willingness to evolve with the industry demonstrates this enthusiasm. “We managed camera wash even though five years ago, ten years ago, camera wash wasn’t on our radar,” Mr. Saxon points out. “Today it very much is and that is because of an ever-changing adaptation within the automotive industry to provide the consumer with a safer, more efficient, more environmentally friendly product. And every day there is a new problem statement that we come to work to solve.”

The newly formed company is expanding rapidly and the feeling of excitement is palpable. “We are growing,” Mr. Saxon reports. “We are growing rapidly; we are growing well. We have 1,700 employees now and of those 1,700 employees every one that I have spoken to is very excited about this merger and the prospects for the future.”